Improve efficiency, reduce risk and control operating costs

Published: June 19th 2020

In a number of industries, operators are increasingly turning to outside contractors to take advantage of consistent maintenance schedules and expert service. Conducted by experienced and well-trained technicians from specialty companies, these contracts have been found to improve safety and control costs.

Specialty contracting may be a better choice for service than internal resources, since the providers are fully trained on the newest equipment designs and safety procedures. In many cases, they may be able to secure replacement equipment more quickly during periods of unscheduled downtime due to their industry-wide contacts.

Performance problems with conveyor components and systems can frequently be traced to improper installation or insufficient maintenance. It’s recommended that the component manufacturer or expert contractor install equipment on both new and retrofit applications. Serious performance problems stem from a lack of proper maintenance. Using a specialty contractor (also known as a ‘certified contractor’) for installation and ongoing maintenance contributes to safer and more efficient production -- with less unscheduled downtime -- and in the long run saves money and reduces injuries.

Training and Retention

The time and resources required to train employees on equipment and certify them to conduct certain procedures such as confined space entry, electrical work, etc. can be a significant ongoing expense. As workers become more experienced and gain certifications to properly maintain efficient systems, their value in the marketplace rises, and retention can become an issue. In contrast, specialty contractors must be experienced, knowledgeable and certified to conduct the appointed maintenance, and it’s up to the contracted company to retain and train that staff.

Maintenance Danger Zones

Due to a greater emphasis on safety and the expensive consequences of unscheduled downtime, bulk handlers are being more meticulous about conveyor operation and maintenance. This increased scrutiny includes regular cleaning of spillage, improved dust control, and additional monitoring and maintenance, exposing employees to a moving system more often. These changes introduce a variety of hazards.

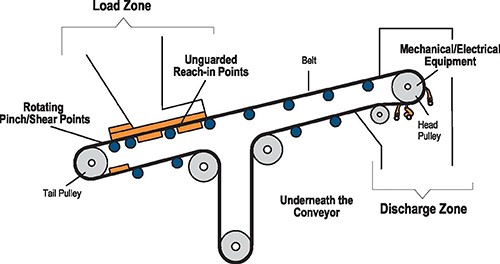

Conveyor danger zones where work injuries are likely to occur:

- Loading zone

- Discharge zone

- Mechanical / electrical equipment

- Rotating pinch/shear points

- Underneath the conveyor

- Unguarded reach-in points

Danger zones exist along the entire length of the belt, many at maintenance points

Most common conveyor-related issues are found across a wide range of industries, and personnel who work around the equipment on a daily basis often become complacent about the conditions, viewing issues as an unavoidable outcome of production rather than abnormalities in need of resolution. An experienced maintenance contractor recognizes these problems and may present solutions that internal resources have overlooked. The improvements are designed to reduce employee exposure, improve workplace safety and maximize productivity.

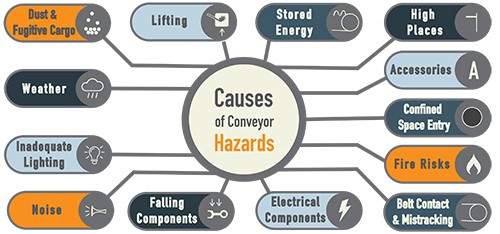

The list of potential sources of hazards is long and varied

Types of Service Contracts

Maintenance programs differ by provider and may be customizable to suit individual customers, but they generally fall into three categories: inspection/report, cleaning/servicing and full service.

Contracted services, such as mobile belt cleaner maintenance, help reduce component failures.

A scheduled inspection and report contract sends a specialty contractor to thoroughly examine a system -- from belt health to equipment function to the surrounding environment -- and identify potential issues. A report is produced that presents findings and offers solutions.

The cleaning and servicing contracts are perhaps the most common. From spillage and silo cleaning to monitoring and changing belt cleaner blades, services can be very specific and fill gaps where maintenance crews might be overstretched. The first advantage to this is that a conveyor can be surveyed without requiring the attention of plant personnel, freeing them to go about their usual tasks. A second advantage is that the outside surveyor is an expert in proper conveyor practices and current governmental regulations.

At the highest level, a full service and maintenance contract sends trained technicians who take accountability for monitoring, maintaining and reporting on every level of system function. They replace wear components when needed and propose required upgrades in order to maximize efficiency, safety and uptime. This provides operators with cost certainty, making it easier to project and manage the cost of operation.

Return On Investment (ROI)

Increasing speeds and volumes on older conveyor systems designed for lower production levels contribute to workplace injuries and increased downtime.[2] Capital investments in newer semi- or fully-automated systems designed for higher throughput require less labor, but the maintenance staff needs to be highly trained and specialized technicians.

Maintenance service contracts deliver the best ROI through a series of factors:

- Compliance – The contractor points out compliance issues and offers solutions prior to expensive fines and violations.

- Injuries / Liability – Contractors rely on a strict set of safety procedures to conduct maintenance, reducing liability.

- Efficiency – Maintenance service contracts focus on improving and sustaining uptime with the least capital investment possible.

- Consistency – Contractors have a clear directive and are not affected by internal factors (labor disputes, morale, etc.).

- Cost of Operation – With a defined scope of work on a set budget, along with clear reporting and recommendations on pending needs, operators can better forecast improvements and control labor costs, further improving ROI over time.

Conclusion

Maintenance service contracts are not just a way of controlling and potentially reducing the cost of operation; they are also a safety mechanism. For example, one case study showed a 79% reduction in lost time incidents and a 40% improvement in production using specialty services, which demonstrated payback in days from an annual specialty maintenance contract.

Workloads may preclude staff from maintaining proper compliance or they just might not notice some violations. Outside resources take ownership of the plant’s efficient and productive use of the conveyor system and strive to improve conveyor efficiency, maximize equipment life and safety to add value to the operation.

At the core of the issue is lower operating costs and improved production. The work should match or improve efficiency regarding downtime and throughput. If the criteria of compliance, cost savings and efficiency are met, then the maintenance service contract has provided a tenable ongoing solution.

References

[1] “Standards: 1926.555 - Conveyors” U.S. Occupational Safety and Health Administration (OSHA), Department of Labor, Washington, D.C. https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.555

[2] Swinderman, Todd; Marti, Andrew D.; Marshall, Daniel: Foundations for Conveyor Safety, Sec. 5, pg 426 (2.7), by Martin Engineering, Worzalla Publishing Company, Stevens Point, Wisconsin, 2016. https://www.martin-eng.com/content/product/690/safety-book

[3] Swinderman, Todd; Marti, Andrew D.; Marshall, Daniel: Foundations for Conveyor Safety, Sec. 6, pg 472-476, “Case Study Return on Safety at a Coal Mine” by Martin Engineering, Worzalla Publishing Company, Stevens Point, Wisconsin, 2016. https://www.martin-eng.com/content/product/690/safety-book