Published: August 2nd 2016

Efficient material flow is a critical element of dry bulk handling, and fugitive material accumulation can have a significant effect on a plant’s profitability. Spillage around conveyors and transfer chutes is a waste of material, typically requiring labor-intensive cleanup that raises maintenance expenses and diverts manpower from core activities, in some cases introducing safety risks for personnel. Although many plants still use manual techniques to remove accumulation, the cost of labor and periodic shutdowns has led some producers to investigate more efficient methods for dealing with this common issue.

Northern Indiana Public Service Company (NIPSCO) is Indiana’s second-largest utility, with a service territory covering roughly the upper 30% of the state. The firm’s customer base is predominately residential, yet industrial users consume more than 50% of the total electricity produced by the utility. Approximately 80% of that power is generated from the combustion of coal.

The Michigan City Generating Station (MCGS), located on the shore of Lake Michigan, has a single 500 MW coal-fired unit. The system burns about 5,000 tons of coal per day, primarily 85% PRB with a 15% eastern blend, metered by a belt feeder onto conveyors that keep the plant’s ten bunkers stocked.

Conveyor Upgrade

The MCGS Maintenance and Engineering departments decided to implement significant upgrades to the conveyor feed systems. By updating the facility’s longest conveyor, company officials planned to reduce fugitive dust, contributing to greater plant safety, productivity and environmental responsibility.

From the outset, engineers planned a proactive approach. To develop a roadmap, they conducted a plant-wide combustible dust assessment and then prioritized the changes they wanted to make, seeking out the best available technologies to eliminate the most pressing problems first.

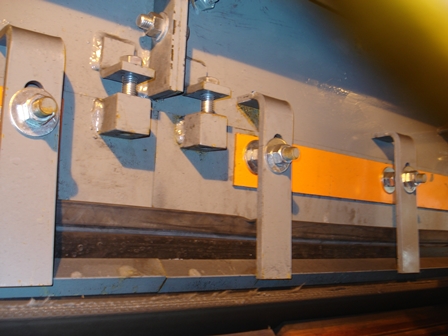

Martin Engineering was selected as a primary resource for the upgrade, including retrofit wear liners on the four feeders below the rail car dump, as well as on the two feeders from the reclaim line. The wear liners are designed to remove the material burden from the dust containment system, so the bulk of the load is diverted away from the sealing components, keeping the coal away from the elastomer seal and extending system life. Available in 3/8" or 1/2" thick abrasion-resistant plate, the liners mount to the outside of the existing transfer point skirtboard.

Minimizing Downtime

Rather than scheduling a full plant outage, the installation was completed during a single-shift outage. A 3-man crew from Martin Engineering first rebuilt the load zone on the belt feeder below the railcar dump, where the skirting and liners were worn out and the support structure below the belt had deteriorated over the years. Next, the technicians pre-fabricated additional support structure to be installed below the idlers, designed so it could be moved into place through very confined spaces. When all sections were replaced or repaired, they went to work on the wear liner and skirtboard.

“Typically, a wear liner is installed on the transfer point skirtboard, where it protects both the steel and the sealing system from abrasion that arises from material loading and flow,” commented Martin Engineering Territory Manager Chris Griffin. “But installing the liner in this conventional position inside the skirtboard makes it hard to install, inspect and replace.”

Martin Engineering's EVO® Modern Conveyor Architecture offers a new concept in wear lining - putting it outside the skirtboard. This technique offers several benefits. For one, it allows precision alignment of steel panels to avoid points that entrap material and damage the belt. The approach also facilitates easier inspection of the liner -- and easier replacement when required -- both without confined space entry. Because the wear liner is directly against the elastomer sealing system (without skirtboard steel between the liner and seal), there is no room for material buildup. This improves the performance of the liner and skirtboard sealing system, without adding to the cost of conveyor construction.

“All work was performed outside the chutes, so we didn’t need a lengthy downtime to install the new components,” commented Martin Engineering Installation Technician Tony King. “Because it’s positioned on the outside, the EVO® External Wear Liner saved labor and eliminated the need for confined space entry, without requiring a full tear-out of the existing chutes.”

Attached on unique mounting blocks, the wear liner is readily adjustable through a specially-designed bolt-on alignment system that delivers precise control to reduce spillage. The components are designed to fit conveyors with trough angles from 0º to 35°. Special cutaways simplify installation, without modifying existing skirtboard supports. Worn internal wear liners can be left in place, as long as there is no risk of trapping material or damaging the belt.

“One of the problems with the existing skirtboard was its proximity to the edge of the belt,” explained Terry Weiler, MCGS Maintenance Supervisor. “There was so little belt edge to work with that sealing became much more difficult,” he said. To address the problem, the Martin Services installation crew cut out a portion of the existing skirtboard and located the new skirts 2" inboard from each side.

To further manage fugitive material, technicians also sealed the belt edge using Martin Engineering’s ApronSeal™ Skirting System, which provides two wear surfaces on a single elastomer sealing strip, installed along the bottom of the skirtboard. When the bottom side of the strip against the belt becomes worn, the sealing strip is inverted to deliver a second service life.

“The dual skirtboard system incorporates a primary seal clamped to the steel skirtboard to retain lumps on the belt and a secondary or ‘outrigger’ strip to capture fines and dust particles that pass beneath the primary seal,” Griffin continued. “The secondary seal lies gently on the belt and self-adjusts to maintain consistent strip-to-belt pressure, despite high-speed material movement and fluctuations in the belt’s line of travel.”

Worn rollers were also replaced with Martin Engineering track-mounted idlers, which are designed with a unique sliding frame on a stationary base. The compact idler set fits into tight spaces between belt support cradles, needing only eight inches (203 mm) of width for 6-inch (152 mm) rolls, yet the slide-in frame allows easy installation and service.

In fact, with the Martin® Trac-Mount™ Idler, there is no need to raise the belt or remove adjacent idlers. “That part of the upgrade was an operator favorite, given the very tight quarters around the feeder belt,” observed Weiler. Idler assemblies can be supplied with either steel or impact rollers.

Results

Together with other recommendations from the study, MCGS enhanced the conveyor systems to significantly reduce spillage, eliminating the dust and material piles adjacent to the coal handling components for improved safety and minimize waste.

“We are pleased with the work of the Martin Engineering crew and the performance of the retrofit wear liner system,” said Weiler. “Because it installed so easily, we could complete the upgrade without an extended outage. It refurbished our system, and really helped us reduce the fugitive material.”

A short time later, MCGS ordered three more rail car dump feeders from Martin Engineering to complete additional upgrades. Weiler also revealed that further plans are in the works: “We are now looking at using the retrofit wear liner to update other conveyors in the plant,” he added.