| Product Types Used | Belt Cleaning Solutions , Primary Belt Cleaners , Secondary Belt Cleaners |

|---|

Problem

As part of frac sand production, the "trash sand" is the leftover material after screening, which is typically very wet and full of debris of various kinds. A plant in the southern USA was having a serious problem cleaning the trash sand conveyor belt with its existing cleaners. Material would cling to the return side and fall off along the belt path, fouling bearings on the take-up so badly that they needed to be changed monthly. Even though the conveyor is about 7 ft from the ground, eventually the pile of accumulation would grow so large that it engulfed the take-up pulley. The company was having to commit labor to cleaning up the spillage every day, taking man hours away from more productive activities.

Solution

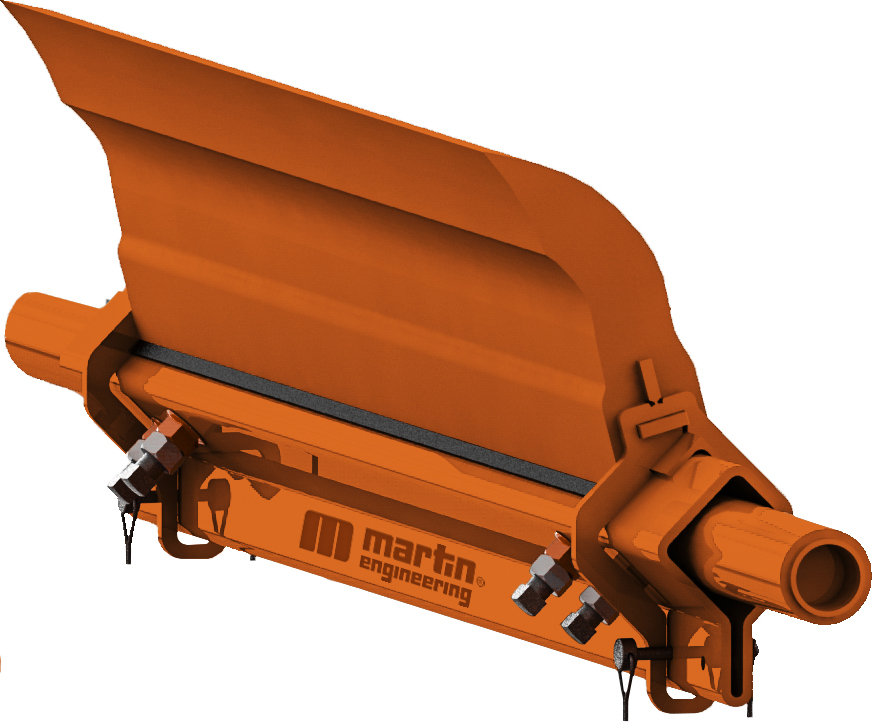

After reviewing the problem, the Mr. Blade technician replaced the existing cleaning system with a Martin QB1 Primary Cleaner and SAF Secondary Cleaner. He also worked with plant personnel to repair the splice: cutting out the old splice, skiving the belt, and grinding the clips to achieve a smooth surface that would transition easily through the cleaners without damaging either the splice or the cleaners. The QB1's patented blade design maintains consistent belt contact and constant cleaning pressure as it wears, so its effective cleaning performance lasts longer. The SQC2S™ Secondary Belt Cleaner incorporates individually-cushioned tungsten carbide blades for effective conveyor belt cleaning without risk to belt, splice or blade.

Result

Operators find that the system is now running clean, with very little carryback apparent, and no further problems of burying the take-up. As a result, the plant has not had to change bearings since the new system came on board. The return on investment (ROI) includes reduced costs for downtime, replacement parts and labor, as well as a savings in man hours that had been spent each day on cleanup. In addition, plant personnel spend less time around the moving conveyor removing spillage, reducing the possibility of injury. Whether based on reduced costs of cleaning and bearing replacement or on potential safety savings, the belt cleaning system investment paid for itself in 4 to 5 months.