Resources

| Product Catalog | Download |

| Tech Data Sheet - Skirting Selection Guide | Download |

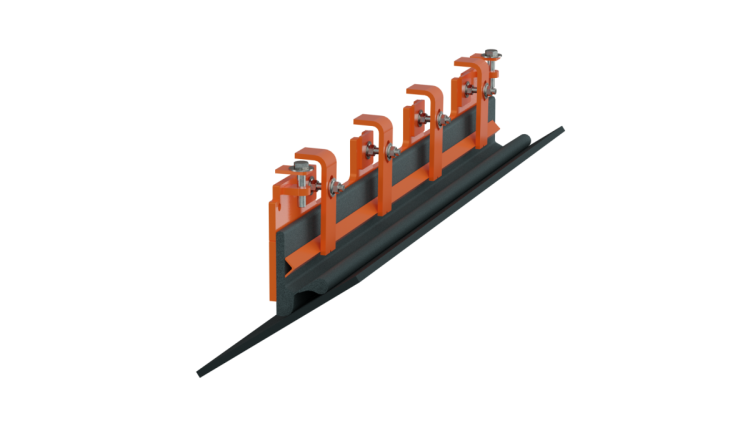

| Tech Data Sheet - ApronSeal™ Single Skirting | Download |

| Operator Manual - ApronSeal™ Single Skirting | Download |

| Operator Manual - ApronSeal™ Single Skirting - Spanish | Download |

| Operator Manual - ApronSeal™ Single Skirting - Portuguese | Download |

| Drawing - ApronSeal™ Single Skirting XHD | Download |