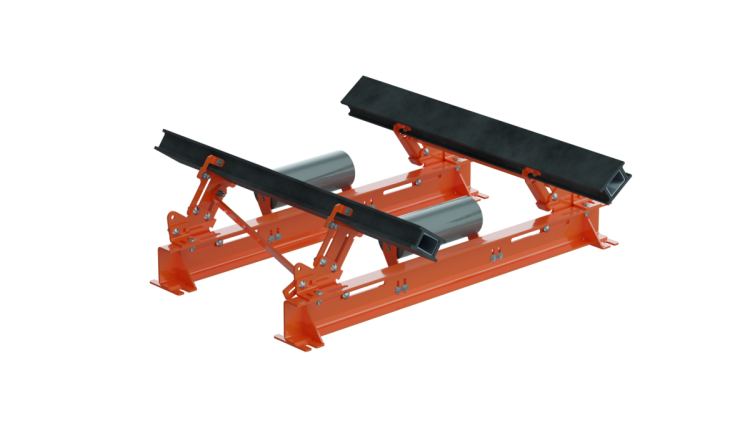

Slider Cradle

Installed under the skirtboard of a transfer point, Martin® Slider Cradles support the edges of the belt to eliminate sag. These cradles prevent transfer point spillage by stabilizing the belt’s path and allow the effective sealing of the belt edge. Cradles are available with high-performance UHMW or Stainless Steel Bars to match application requirements.

Features and Benefits:

- The Martin® Slider Cradle supports the belt edges, allowing an effective seal

- Slider Cradle eliminates pinch points where trapped material can gouge the belt

- Conveyor belt glides over UHMW bars without heat buildup

- Use both top and bottom of unique "box bar" to provide dual-wear surfaces for double wear life

- Slider Cradle adjusts for wear easily with simple tools

- Fits any troughing angle. One bar per side for belts 18 (457 mm) to 42 inches (1067 mm); wider belts require two bars per side. Center bar or rollers may be required.

- Protected by U.S. Patent No. 4,898,272

Our technicians and engineers are available to provide expert advice and assistance on this product and all of your bulk material handling questions and problems. Please contact us today and let us help!

We Solved Their Problems!

Let us help you solve yours as well. All products and services provided by Martin Engineering carry our Absolutely No Excuses Guarantee. If we don't solve your problem, we will fully refund your money or provide a different solution for you. Period.

Filtrating Dust At Environmentally-Conscious Coal-Fired Power Plant

Orlando Utilities Commission – Stanton Energy Center (SEC) wanted to increase safety by limiting dust and spillage from one of its principal conveyors. Engineers wanted to reduce airborne particles, eliminate a potential source of trips and falls, and reduce clean-up and maintenance time, allowing critical manpower to be utilized elsewhere.

Installing Dust Containment Solutions at Sugar Processing Plant

A sugar processing plant in California handles approximately 10,000,000 tons of raw sugar per year through their plant. One of the transfer points was giving them trouble with spillage. They contacted Martin distributor Applied Conveyor Technology (ACT) for their recommendation. ACT recommended upgrading the transfer point with cradles, wearliner, dust curtain and skirting.

Transfer Point Solutions Result In Safer, More Productive Coal Mining

A coal mining facility in China was experiencing dust and spillage from one of its conveyors. Fugitive dust lowered the air quality, clogged equipment and had the potential to affect workers’ health. Misalignment of the belt caused piles of lost product that had to be cleaned up, reducing system efficiency and wasting labor hours.

Transfer Point Products Improve Severe Spillage And Dust Problems

At a cement plant in Kentucky, the clinker transport system had severe problems with the escape of spillage and airborne dust in the loading zones of three conveyors. Martin® Transfer Point Solutions were recommended to stop the spillage and dust problems. To improve the clinker conveying, the plant agreed to upgrade the transfer points.

Belt Support System Allows For 24/7 Operating Schedule

A major expansion at a gold mine included an innovative idler design developed by Martin Engineering in conveyor transfer areas. The mine’s high-capacity conveyor system faces continuous loads and heavy impact from 8-inch lumps of copper ore. To withstand this impact, Martin Engineering designed a special belt support system.

Spillage Problems Corrected By Transfer Point Redesign

A coal-fired power plant was suffering from extensive spillage and other problems. The plant’s coal-conveying system needed an extensive upgrade, including new belt cleaning systems and improved transfer point systems.

MartinPLUS® Installation Services Redesign Power Plant Transfer Points

An energy company in Lansing, Iowa was facing severe spillage problems in underground loading points. The steel structure on part of conveyor feeding system was shot. It was old and worn out. There were bows and dips in the skirtboard, and it wouldn't stay sealed. This created excessive dust and spillage in the tunnel.

Power Plant Needs Cleaner, Safer, More Productive Material Handling System

The Warrick Power Plant is operated by the Alcoa Generating Company to supply electricity for smelting operations at Alcoa’s Warrick facility. The plant’s coal handling equipment needed reconstruction and improvement, including improved systems to control spillage and dust, to provide a cleaner, safer and more productive coal handling system.

Transfer Point Solutions Resolve Carryback At Kentucky Energy Plant

An energy company in Kentucky was having problems with carryback on their side-by-side transfer belts carrying coal from the central reclaim tunnel to the bunkers. They hired Martin Engineering to find a solution. Martin recommended a variety of belt support, belt sealing, tail protection and dust containment solutions as well as safety accessories.

Transfer Point Solutions Solve Fugitive Cargo Issues

A cement plant was experiencing increased costs due to fugitive cargo and dust piling around the plant’s petroleum coke conveyor transfer point. The material blocked access, degraded conveyor components and required expensive maintenance. Outsourced labor using rented equipment needed weekly downtime to clean the area, further raising the cost of operation and lowering production.

Martin Products Help World's Highest Production Coal-Fired Power Plant

A coal-fired power plant produces over 300,000 tons per day. The plant was having trouble with dust and spillage at the conveyor transfer loading point in addition to excessive spillage and piles of fugitive materials under the conveyor belt. The problem led to manual cleaning and an increase in maintenance costs, resulting in regular and costly down-time and man-hours.

Cement Plant Needed Transfer Point Solutions

Lafarge Cement was experiencing excessive spillage from one of its conveyor belts. The material was a mix of sand and water. Every time the extractor started, a mixture of sand and water discharges and the conveyor belt could not contain the material, in its current design. Martin Engineering was called to inspect the system and recommended a complete upgrade of the transfer points.

Salt Buildup At Chemical Plant Causing Frequent Shutdowns

At the Arkema Group chemical site in France, a salt storage facility that stores and supplies salt had developed a lot of buildup from carryback along the belt. This buildup required a stop every six months for manual clean-up. After reviewing the system, Martin Engineering recommended two solutions.

Belt Support Products Solve Fugitive Dust And Spillage Problems

A coal plant had spillage and dust issues at two conveyor transfer points, because material was loaded onto the belts traveling 500 fpm with little control over impact or settling. The result was excessive fugitive dust throughout the facility. Inadequate chute control caused spillage to get caught between the belt and rubber tail pulley, damaging both.

Martin Engineering Offers Dependable Solutions When Others Fail

A mine was experiencing dangerous spillage at the loading zone of its tower mounted conveyor. Despite installing equipment from a previous supplier, workers found that dust filled the tower and chunks of raw material spilled from the transfer chute onto the stairs, creating a potential workplace hazard. Twice a month operations had to be disrupted for 12 to 24 hours, so that a 4 to 5 person team could clean spillage.

Martin Provides Effective Belt Support Solution

A coal-fired plant handling large quantities of synthetic gypsum was experiencing fugitive material problems, with dust and spillage piling up and large chunks of gypsum falling off the belt. Martin technicians determined that inadequate belt support was the primary cause of the problem, allowing material to escape from the transfer point’s loading zone.

Martin Transfer Point Solution Saves Mainframe

A nickel mining plant was experiencing excessive equipment wear and damage at a main transfer point leading from the rotary dryer, handling 71,430 tons per month of bulk material. The impact force of cargo on an unsupported belt was cracking idlers and bending the mainframe. The damage forced operators to shut down the entire system regularly to repair mainframe damage and replace broken equipment.