Reduce the time and cost of installations and maintenance.

In the harsh environments where our products are in use, regular routine maintenance is just part of the business. At Martin Engineering, we manufacture quality products that are easier to install and simply more durable, while lasting longer with a consistently predictable service life. Plus, we offer solutions that keep conveyor belts clean and correctly aligned and minimize dust intrusion, which helps all your other equipment last longer before needing maintenance or replacement.

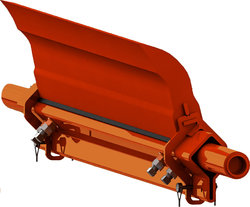

Our products are designed and manufactured with ease of installation and maintenance in mind. For example, our belt cleaner blades can usually be installed by one person in a just few minutes, and we have designed innovative nozzles for air cannons that can be serviced without removing the air cannon.

Also, we design and engineer our products so that they perform over a consistent, predictable service life, which allows you to more easily perform maintenance and replace equipment during scheduled shutdowns.

If you are concerned that your operation spends too much time and money on maintaining and replacing equipment, talk to one of our experts. We’re standing ready to listen to you describe your operation and offer recommendations on how you can improve the situation. Our technicians and engineers are available to provide expert advice and assistance on all of your bulk material handling questions and problems.

Martin® GravitySeal™ Self-Adjusting Skirting Maintains Effective Seal Without Maintenance

Martin® Maintenance Helps Steel Plant Overcome Regulatory Issues

Belt Sealing Products Reduce Cleanup and Maintenance Costs

Martin® Maintenance Services Improve Mining Operation

Transfer Point Redesign Reduces Spillage And Dust

Foundations™ Operations & Maintenance Workshop Dramatically Improves Productivity

Martin® Forever Belt Cleaner Guarantee

We are so confident in the performance of our belt cleaners that we proudly offer the industry's first Forever Belt Cleaner Guarantee, an exclusive offer available for current genuine Martin® replacement blade customers. We will provide Martin® replacement tensioners and mainframes for any belt cleaner assemblies as required – whether the ones we're replacing were manufactured by us or not – absolutely free of charge for as long as we have a service relationship including FREE blade installation, tensioning and hardware upgrades, helping to maintain maximum performance and keeping your belt cleaning system running in like new condition – FOREVER!

Learn More About Our Guarantees Here

Save With Our Martin® Walk the Belt™ Service!

Every conveyor is different, even within the same facility! We can provide regularly-scheduled reviews of your bulk material handling system components, involving a specialized crew with the expertise necessary to achieve high operating standards, keeping the conveyor system running at maximum productivity. Immediate data and photos will be available to facility managers and our suggestions will ensure long-term savings and efficiency.

Get Your Belts Reviewed By People Who Know What They’re Looking At -- At No Charge!